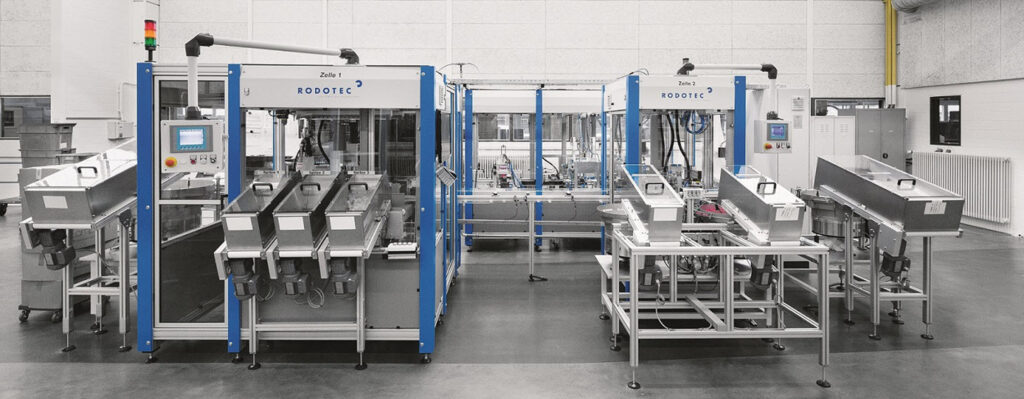

Individual automation solutions

Automation and process optimisation is a matter of trust

Ensuring the economic efficiency of production requires constant adaptation to the increasing demands of customers and markets. This requires flexible automation technologies.

Concepts optimally adapted to the respective industry requirements represent the only solution for long-term, sustainable competition. RODOTEC sees itself as a partner who offers its customers the optimum solution for their requirements and applications, from the product development phase right through to commissioning.

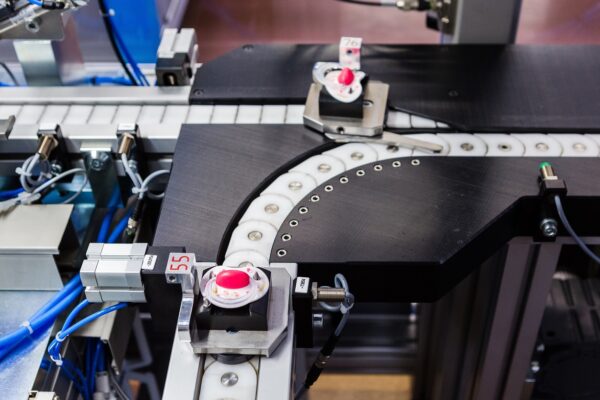

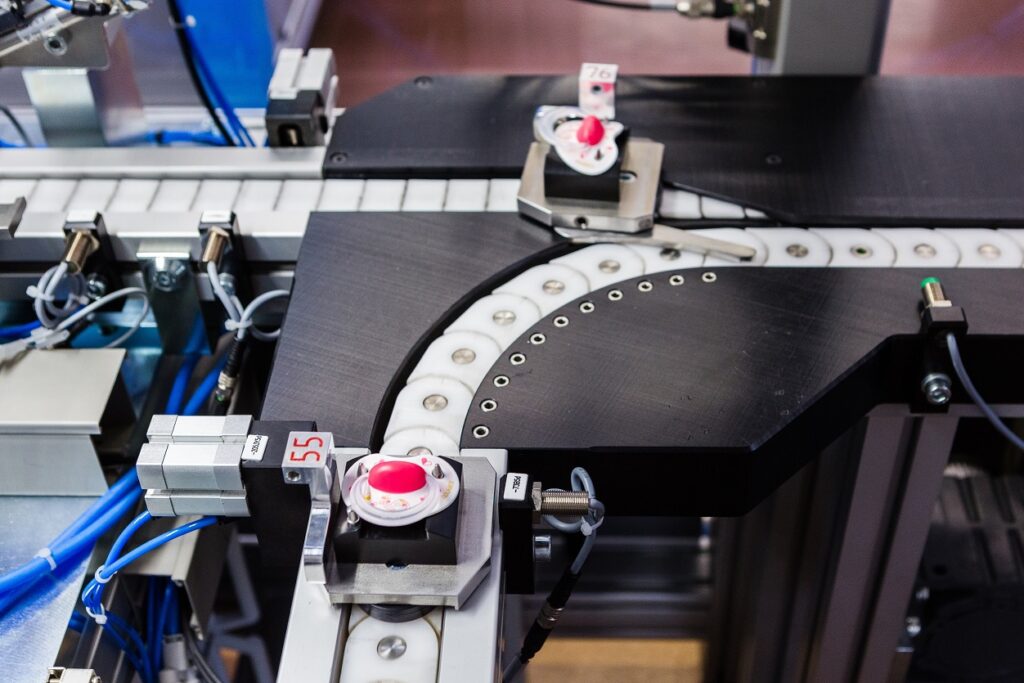

Our services in special machine construction

Assembly Systems

Manual Workstations

Transfer Systems

Testing Systems